Shipping of Big Bags

3 July, 2020

Shipping of Big Bags

The shipping of big bags, jumbo bags, bulk bags or Flexible Intermediate Bulk Containers (FIBCs) is the preferred option for dry material bulk transport. If the big bags are stored in the vessel’s holds, where they’re protected against external factors which could alter the quality of the transported products, they can be set in place without a container.

It’s because a ships’ holds are protected from weather and dry and the only cases when the big bags are exposed are during loading or unloading operations.

But if the big bags are loaded on the carrier’s deck, then intermodal containers are used to keep the big bags secure and protected. Intermodal containers are exposed to weather factors such as torrential rain or storms while crossing international waters, but the big bags inside are safe and dry if they’re loaded correctly.

Discover our Safety Products

What Is a Big Bag?

Bulk bags, jumbo bags, big bags or flexible intermediate bulk containers (FIBCs) are industrial containers designed to secure and transport flowable goods such as fertilizer, sand, plastic granules, or coffee beans. Usually, they’re made of flexible materials such as polyethylene or woven polypropylene, which are both safe by-products of crude oil.

They’re clean, eco-friendly, recyclable and cost-effective. One of the main advantages of using big bags for shipping is the capability of holding huge volumes of goods compared to their own weight.

This has a direct positive impact on the overall freight costs. Also, big bags are very easy to handle during automated loading and unloading, without requiring manual handling, which makes them safer than other solid product containers. And big bags also maximize the available space in vessels’ holds for shipping bulk goods and in intermodal containers.

How to Load a Bulk?

When handling or lifting a bulk bag, you’ll find a variety of guidelines because improper stowage and handling can lead to serious accidents. FIBCs are transported by lifting in loops. You’ll find big bags with 1, 2 or 4 loops on the top, depending on if they’ll be lifted by forklift or cranes. And for easier handling with forklifts, the big bags can also be transported on pallets.

Big bags are filled from the top and unloaded from the bottom. Big bags must be loaded onto vessels in accordance with the International Load Line Convention and SOLAS for the International Cargo Ship Construction Certificate, to avoid the capsizing of the carrier.

To prevent the shipping of cargo, the regulations of SOLAS Chapter VI, the Code of Safe Practice for Cargo Stowage and Securing and the Carriage of Cargo must be abided.

Newsletter

Sign up for our newsletter and get the latest news from elebia

Some Safety Recommendations

The Flexible Intermediate Bulk Containers Association, or FIBCA, is the most important association for manufacturers, distributors, and users of big bags. Throughout the entire process, you should consider the weight limit of the big bags. Improper loading or filling operations can lead to accidents.

To properly fill an FIBC you should start by checking if it’s damaged. This could compromise its strength or transportation capability. Check that the discharge chute is sealed properly. Also, while filling the big bag, make sure that the product is distributed evenly and that the bag is stable while it’s being filled.

When lifting a FIBC, ensure that it’s intact. Check that the lifting mechanisms can handle the weight of the filled bags. Also, use hooks, forks lifts or bars which are not sharp and exclusively have rounded edges with a minimum 5 millimeter radius. And only use lifting equipment, which is specifically approved for handling big bags.

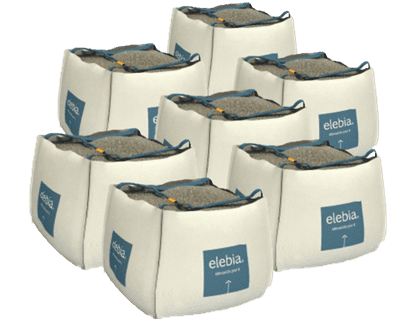

Elebia’s Big Bags, An Easier Solution

Elebia redesigned big bags to offer optimized storage and transportation solutions for dry products in bulk. The new design and the automated special hook facilitate remote lifting and release onto the sea carrier. So, manual manipulation is not involved.

The standard 4 corner loops were removed and the bags were re-designes, adapting them to the new automated lifting hooks. Now, these bags have two side handles and a sling in the middle, which includes metal wiring. The metal attracts the automatic hook towards it. Only one point is required to activate the lifting of the big bags.

This new design also allows for 2 big bags to be loaded simultaneously, which increases the handling productivity rates. The Elebia big bags are perfect for processing factories because they significantly reduce the handling chain from filling, initial transportation to the carrier, stowage, and final dispatch.

The Elebia big bags are designed in standard 90 x 90 x 100 cm sizes or customized according to the clients’ requirements.

It’s a fact that big bags have increased in popularity thanks to their flexibility, versatility, strength and lower handling and transportation costs. But the new Elebia’s design it is possible to improve the efficiency of big bags and optimize the existent qualities of these industrial containers.

Elebia has managed to innovate the bulk bag concept and disrupt the usual handling operations to increase safety and lower manipulation costs.

Products Made For Your Company