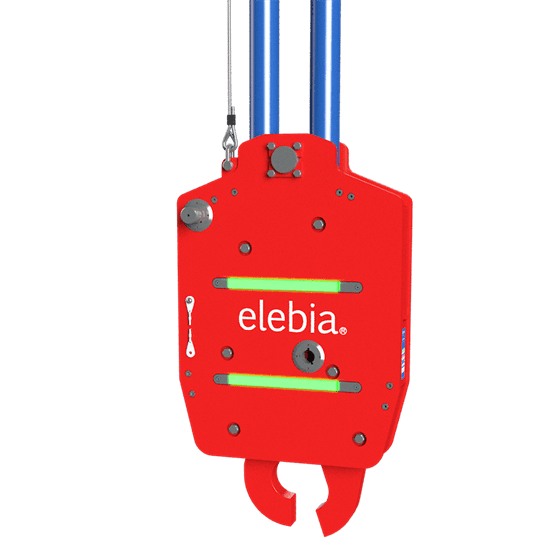

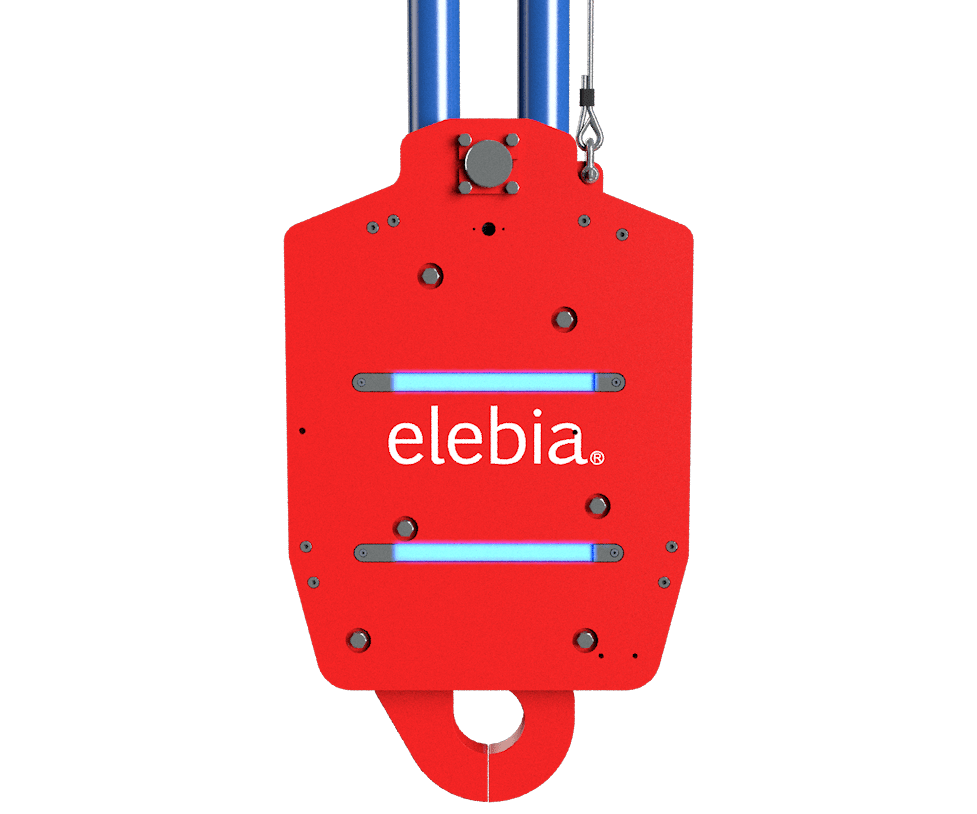

The Dropper Automatic Load Drop Hook

Automatic Load Drop Hook

The Dropper10 is a 10 Tonne automatic load drop hook that allows you to release any load safely and at a distance with the use of the eMAX remote control.

It prevents the need to work at height, enabling the load to be disconnected at a

distance without the need to climb onto the load for the release operation.

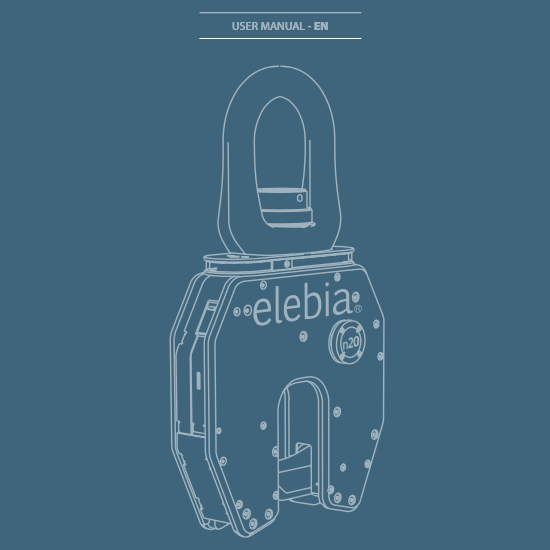

How does it Work?

The Dropper maintains the state of the last load-release operation. (The safety pin is inserted in the top slot, the hook is open and LEDs are green).

Manually close the hook and change the position of the safety key pin to the bottom slot (Fig. 3) and once inserted, turn it 90 degrees to the right (cw). This action activates the autoclose sensor which gives the order to lock/close the safety latch, activating the LEDS from green to red. (transition time of approx 15 seconds) The process ends correctly when the LEDs change to blue.

Place the shackle which carries the load and once ready, remove the safety key pin from the bottom slot placing it back onto the top slot and turning it 90 degrees so that it locks/closes. It is at this point that Dropper10 is ready to release the load.

To release the load, press the eMAX “X” button to activate the operation. During the opening transition the LEDs are red (transition time of 7 seconds) Once the loaad is released, the hook returns to its initial state.

In Detail

The Minimum Releasable Weight is 50 kgs./110 lbs.*

(For lower values, please contact the sales department.)

High-Brightness LED

Status Indicator *

The dropper maintains the state of the last load release operation. The mobile/movable hook is open and the LEDs are green.

Closing transition with red LEDs. Transition time of approximately 8 seconds.

The process ends correctly when the LEDs change to blue and the closure of the lock is confirmed.

Green: Dropper is Open / Unblocked

Red: Transitioning to Closed: Do Not Lift!

Blue: Dropper is Closed / Blocked

White: Low Battery

Load Cell *

The Dropper can be equipped with a load cell to weigh the load that is being lifted.

Load cells are used for quick and precise measurements and compared with other sensors,

they are relatively more affordable and have a longer life span. Their main purpose in our

hooks is to weigh or check the amount of load that is being lifted and to prevent overloads.

The load cell in combination with the eMAX remote control transforms the

automatic load drop hook into a precise weighing scale with advanced features.

* This feature is optional

Specifications

| Load Cell Type | Compression/Flexion Ring |

| Material | Stainless Steel |

| Protection | IP67 (EN60529) |

| Nominal Capacity (Ln) | 10,000 |

| Precision Class | 0.2% |

| Minimum Dead Load | 0% Ln |

| Service Load | 120% Ln |

| Ultimate Load | 500% Ln |

| Total Error | < ±0.2% Sn |

| Repeatability Error | < ±0.08% Sn |

| Temperature Effect: | |

| on zero | < ±0.01% Sn / 5 ºK |

| on sensitivity | < ±0.01% Sn / 5 ºK |

| Creep Error (30 min.) | < ±0.03% Sn |

| Temperature Compensation | -20ºC to 50ºC |

| Temperature Limit | -30ºC to 70ºC |

| Nominal Sensivity (Sn) | 2 ±0.25% mV/V |

| Nominal Input Voltage | 10V |

| Maximum Input Voltage | 15V |

| Input Impedance | 800 ±30 |

| Output Impedance | 700 ±5 |

| No Load Input | < ±2% Sn |

| Insulation Resistance | > 5,000 M |

| Maximum Deflection (at Ln) | 0.4 mm. |

High-Capacity Battery

With the high-capacity battery, a simple 3 hour charge allows for

more than 3.000 cycles or over 250 hours in standby mode.

The battery remains protected from accidental impacts as the slot cover is protected

with a safety lock which protects the battery from falling in case of impact.

Autoclose Mode *

The safety pin activates the autoclose function.

In order to insert the safety pin, the hook must be closed manually.

If the hook is open, the safety pin can not be inserted.

Once the safety pin is properly inserted and rotated to activate the

autoclose system, it locks and cannot be removed during the closing process.

When modifying the position of the safety pin and inserting it in the bottom slot,

the autoclose sensor activates itself and gives the order to lock the safety latch.

Remote Controlled Release

The Dropper is to be used with the eMAX remote control.

Shackle

The Dropper10 is supplied with a shackle. The Green Pin® Bow Shackle BN is a bow shackle with a safety bolt. The shackle offers a double safety (split pin and safety bolt) which prevents accidental unscrewing of the pin.

| Material | bow and pin high tensile steel, Grade 6, quenched and tempered |

| Safety Factor | MBL equals 6 x WLL |

| Finish | hot dipped galvanized |

| Temp. Range | -40°C up to +200°C |

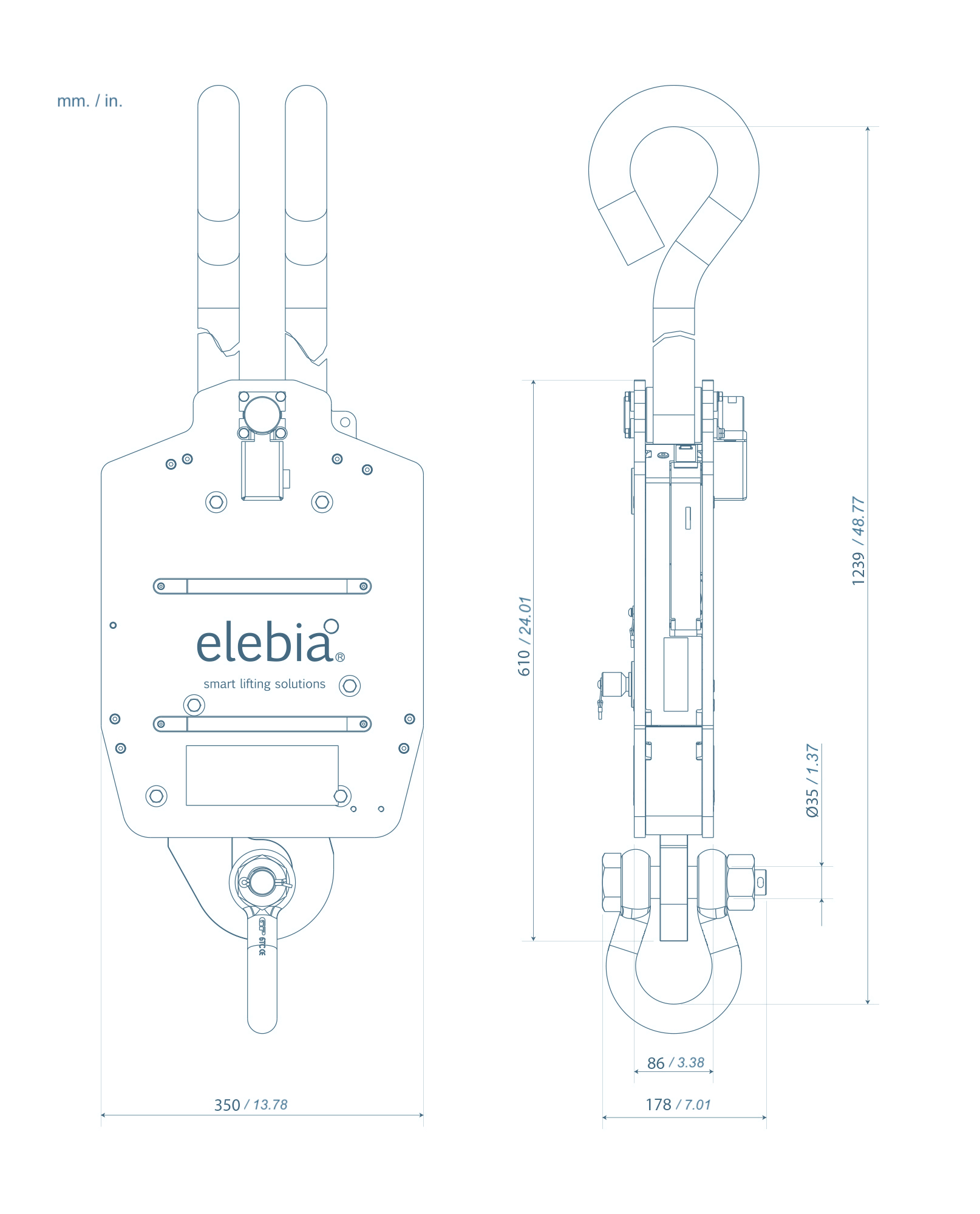

| Diameter Pin | 35mm. / 1.37in. |

| Certification | 2.1 / 2.2 / 3.1 / MTCa / ABS PDA / ABS MA / |

| DNV 2.7-1a / DNV 2.7-1b / DNVGL-ST-0378 / CE | |

| Standard | N 13889 and meets performance requirements of |

| US Fed. Spec. RR-C-271, Type IVA, Class 3, Grade A. | |

| From 2 t and upward these shackles comply with ASME B30.26 |

Regulatory Standards

The Dropper10 certifies with the following regulatory standards:

| EN ISO12100:2012 | EN 61000-6-4:2002 |

| EN 61000-6-2:2002 | EN 60204-1:2007 |

Directive on Machine Safety (D2006/42/EC).

EMC Directive (2014/30/EU).

Low Voltage Directive (2014/35/EU).

Radio Equipment Directive (2014/53/EU).

Assurance of Production Quality in accordance with ISO9001.

ARIB Construction Design Certification Number 203-JN0689.

FCC Identifier 2ACLHEVO for Equipment Class: Digital Transmission System.

Each mechanism is delivered with the CE stamp and a declaration of CE conformity.

elebia is a member of F.E.M. (European Federation of Materials Handling).

Quick Links

Schedule a Demo

See in person how your company

can benefit by using the

Dropper10 load drop hook.