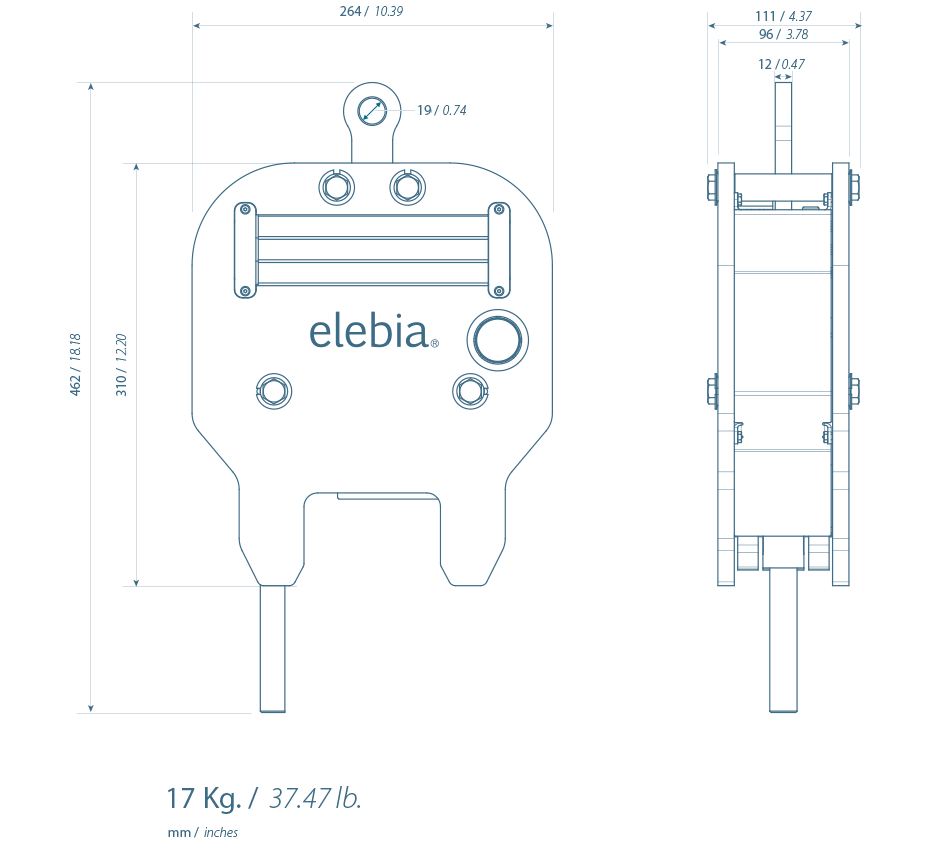

eTrack Rail Lifting Clamp

How Does it Work?

The eTrack rail lifting clamp approaches, orients and positions itself directly on

the rail thanks to the finger. Once in position, the crane descends,

the spring loaded finger retracts and allows the clamp to make contact with the rail.

The eTrack clamp has been tested on the following rails:

45E2, 49E1, 50E3, 54E1, 54E3, 56E1, 60E1, 60E2 rail profiles and 75 conductor rails.

The eTrack is likely to be compatible with the following references but must depend on real tests:

49E1A2, 60E1A1 and 60E1A5.

In Detail

LED Status Indicator

The eTrack’s LED Status Indicator is another feature that helps minimise risks and

enhance safety in the lifting, transporting and turning of rail profiles. The colour coded

scheme shows the rail lifting clamps’ status at all times, and is visible from the operator’s position.

Green: Clamp is Unlocked / Release Load

Red: Intermediate: Do Not Lift!

Blue: Clamp is Locked / Lift & Manoeuvre Load

White: Low Battery

Efficient Battery

The 14 segment E-ink charge status display of the rechargeable li-ion battery for the

eTrack rail lifting clamp guarantees its optimal autonomy and minimum consumption.

The slot cover is also protected with a safety lock which

protects the battery from falling in case of impact.

Smart Nap

The “Smart Nap” mode reduces battery consumption by

activating the color code scheme of the LED status indicator

when the eTrack lifting clamp initiates its locking movement.

Until then, the rail clamp is in suspension mode

and its electronics and battery are not active.

A simple 3 hour charge allows for more

than 5.000 cycles or over 2 months in standby mode.

Autoclose Mode

When the eTrack’s sensor makes contact with the surface of the rail, the clamping

mechanism automatically unlocks. When the ascending maneuver begins, tension is applied

to the clamping mechanism which automatically locks onto the rail, allowing to raise the load.

The eTrack provides a reliable and fail-safe grip on the rail, and has a narrow profile

to ease the approach and positioning to an individual rail when rails are side by side.

Check it Out!

Finger

The eTrack has a retractable spring loaded finger that serves as a guide

to orient and center the correct positioning of the rail clamp.

Fail-safe

Thanks to its fail-safe design, and like

the rest of our smart lifting solutions,

once the rail lifting clamp has locked the rail, it is not

possible to release or drop the load that is being lifted.

Remote Controls

The eTrack rail lifting clamp can be paired to the eMAX remote control,

the eMINI remote control or the eINST installable remote control.

Send all the necessary orders and receive all the info from

the rail lifting clamps straight to your preferred remote control.

See the eTrack Rail Lifting Clamps in Action!

Regulatory Standards

The eTrack rail lifting clamp certifies with the following regulatory standards:

| EN 10204 3.1.B | ETSI EN 303 446-2 V1.1.0 | UNE-EN 60730-1:2013 |

| ETSI EN 300 220-1 V3.1.1 | UNE-EN 1050 | UNE-EN 61000-6-4:2007 |

| ETSI EN 300 220-2 V3.1.1 | UNE-EN 13135:2013 | UNE-EN 61000-6-2:2006 |

| ETSI EN 303 446-1 V1.1.0 | UNE-EN 60204-1:2007 | UNE-EN ISO12100:2012 |

Directive on Machine Safety (D2006/42/EC).

EMC Directive (2014/30/EU).

Low Voltage Directive (2014/35/EU).

Radio Equipment Directive (2014/53/EU).

Assurance of Production Quality in accordance with ISO9001.

ARIB Construction Design Certification Number 203-JN0689.

FCC Identifier 2ACLHEVO for Equipment Class: Digital Transmission System.

Each mechanism is delivered with the CE stamp and a declaration of CE conformity.

elebia is a member of F.E.M. (European Federation of Materials Handling).

Quick Links

Schedule a Demo

Want to see in person how your

company can benefit by using

the eTrack rail lifting clamp?