Subsea Hook

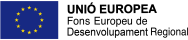

For years we have been approached for a solution to the possibility of carrying out loading and unloading operations in subsea environments. More specifically in underwater lifting operations. Lifting hooks play an important role in ensuring the success of any subsea lifting operation. In other words, there are countless operations that are carried out under water and where the application requires that a subsea hook must be submerged. And at the same time release the load remotely, from a distance.

The subsea automatic hook is designed with a marine configuration (electro zinc coating; fast drying two-component epoxy primer; a two component, high solids, low VOC epoxy micaceous iron oxide coating formulated on proprietary polymer technology which provides rapid cure and overcoating even under low temperature conditions; and a patented high performance, high volume solids content acrylic polysiloxane cosmetic finish providing excellent long term durability.) And it is specifically wired for use in complex marine environments with a high degree of salinity.

The printed circuit board (PCB) and the lithium ion battery are removed from the automatic hook. They are placed in a cylinder that is watertight, but which must remain out of the water at all times in order to maintain radio communication with the remote control. In addition, this cylinder also features an external radio frequency antenna and LED status indicator, providing visual confirmation of hook status at all times.

The motor, which remains in the marine-configured hook, is isolated by an internal cylinder from the possible influence of water within the frame structure and is hermetically sealed for additional protection.

The subsea automatic hook and the subsea cylinder are connected by a transmission cable of up to 30m. maximum length.

Quick Links

Hook Configurator

Personalize and configure

your lifting hook for cranes

and any of its accessories.

Schedule a Demo

Need or want to see in

person which automatic hook

best fits your needs?